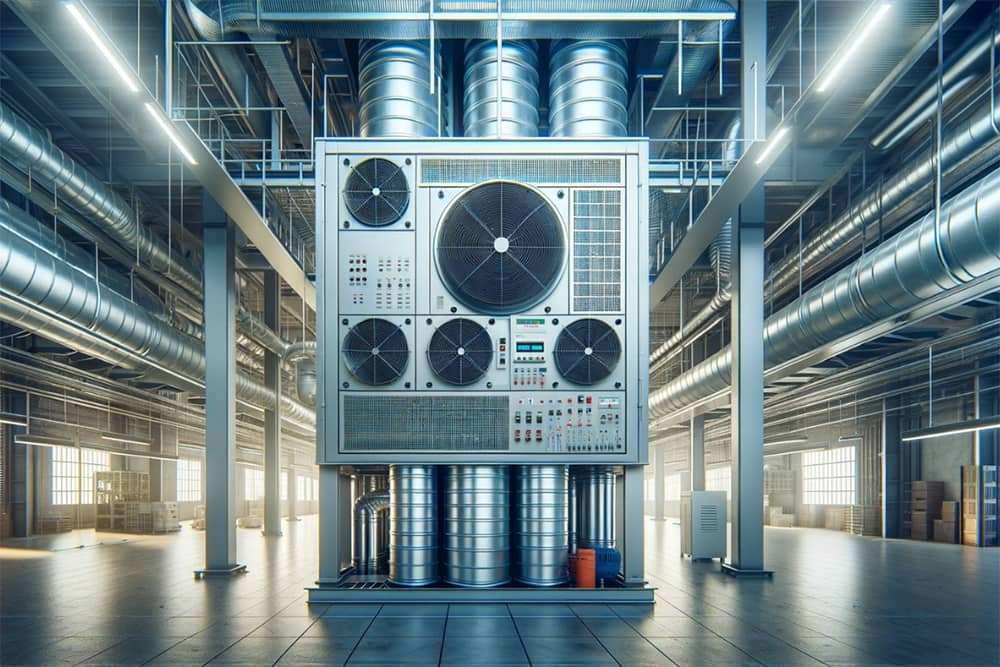

Make-Up Air Units

Industrial Make-Up Air Units (MAUs) are a cornerstone technology in modern commercial and industrial buildings, playing a vital role in maintaining optimal indoor air quality. These specialized systems are engineered to replenish the indoor air that is continuously exhausted due to various operations such as manufacturing processes, cooking, or chemical handling. MAUs draw in fresh, external air, which is filtered, conditioned, and introduced into the building environment. This process is essential for offsetting air removed by exhaust systems, thereby preventing negative pressure situations that can lead to various issues, including backdrafts, poor air quality, and uncomfortable indoor environments.

Understanding how MAUs function is crucial for businesses and facilities that rely on clean, controlled air. Whether it’s a bustling restaurant kitchen, a sterile hospital ward, a precision laboratory, or a busy manufacturing floor, MAUs ensure that fresh, clean air is constantly circulating. This introduction sets the stage for an in-depth exploration of the critical role of MAUs in various settings, their technological underpinnings, benefits and drawbacks in different industries, and best practices for balancing indoor air quality and efficient operation.

The Critical Role of Make-Up Air in Building Ventilation

Make-Up Air Units (MAUs) are pivotal in maintaining a healthy and balanced environment in commercial and industrial settings. These systems are crucial for replacing air exhausted from buildings due to activities like manufacturing, cooking, or chemical processes. By introducing fresh outdoor air, MAUs ensure a constant supply of clean air, helping to control humidity and temperature and reducing the concentration of indoor pollutants. This process is vital for maintaining indoor air quality and providing occupants with a comfortable and safe environment.

How Make-Up Air Units Prevent Indoor Air Contamination

The core technology behind MAUs is designed to combat indoor air contamination. These units work by drawing in external air, filtering it, and conditioning it to match the indoor environment. This includes adjusting the temperature and humidity levels to match the building’s requirements. By doing so, MAUs help dilute and displace contaminated indoor air, which might contain pollutants like carbon dioxide, volatile organic compounds (VOCs), and particulates from various sources. The continuous inflow of fresh air is essential in spaces where exhaust systems are heavily used, as it prevents negative pressure that could lead to backdrafts and further contamination.

Pros and Cons of Make-Up Air Units in Various Industries

In Restaurants:

Pros:

- It helps remove cooking fumes and odours.

- Balances humidity, enhancing comfort and food preservation.

- Cons:

- It can be energy-intensive due to continuous operation.

- Requires regular maintenance to ensure hygiene and efficiency.

In Hospitals:

Pros:

- Ensures a sterile environment by reducing airborne contaminants.

- It is essential in operating rooms and isolation wards for controlling air quality.

- Cons:

- High costs associated with advanced filtration systems.

- Requires precise control to maintain specific environmental conditions.

In Laboratories:

Pros:

- Removes hazardous chemical vapours and maintains clean air.

- Critical for safety in research and testing environments.

- Cons:

- Complex systems are needed for handling diverse types of contaminants.

- Regular calibration and maintenance are essential for accuracy.

In Manufacturing Facilities:

Pros:

- Vital for removing airborne particulates and industrial fumes.

- It helps maintain a consistent indoor environment for product quality.

- Cons:

- It can be costly to install and run, especially in extensive facilities.

- Requires robust systems to handle heavy-duty air contamination.

Balancing Indoor Air Quality with MAUs

Implementing optimal ventilation and air quality strategies with MAUs involves several key considerations:

- The capacity of the MAU must match the building’s exhaust rate to maintain balanced pressure.

- Integrating MAUs with the building’s HVAC system allows for more efficient temperature and humidity control. Regular indoor air quality assessments can guide MAU settings adjustments to ensure optimal performance.

- Using energy recovery ventilators with MAUs can enhance energy efficiency by pre-conditioning the incoming air.

Industrial Make-Up Air Unit Repair and Maintenance

Maintaining Industrial Make-Up Air Units (MAUs) is not just a routine task; it’s a critical process that ensures these units function effectively and efficiently over their lifespan. Given the crucial role MAUs play in maintaining indoor air quality and building pressure balance, their upkeep demands a comprehensive and proactive approach.

Regular Inspections and Immediate Repairs:

Regular inspections are the first and most crucial step in MAU maintenance. These should be scheduled at regular intervals and involve a thorough examination of all components. Key elements to inspect include filters, ducts, fans, and mechanical parts. Particular attention should be paid to wear, corrosion, or damage signs. Immediate repairs or replacements of faulty components are necessary to prevent minor issues from escalating into significant system failures.

Filter Maintenance:

Filters in MAUs play a vital role in ensuring that the incoming air is free from contaminants. Over time, these filters can become clogged, reducing the unit’s efficiency and potentially compromising air quality. Regular cleaning and timely replacement of filters are essential. More frequent filter changes may be necessary for environments with high particulate matter.

Duct Cleaning and Inspection:

Ducts form the pathway through which the conditioned air travels. Over time, they can accumulate dust and debris or even sustain damage or leaks. Regular cleaning ensures optimal airflow and prevents contaminants from entering the indoor space. Inspecting ductwork for leaks or damage is also crucial, as this can lead to energy inefficiencies and imbalanced air distribution.

Calibration of Sensors and Controls:

The sensors and controls of an MAU must be calibrated regularly to ensure accurate operation. This includes thermostats, humidity sensors, and CO2 sensors, among others. Proper calibration ensures that the unit responds appropriately to changes in indoor conditions, efficiently maintaining the desired environmental parameters.

Mechanical Component Maintenance:

The mechanical components of an MAU, such as motors, belts, and bearings, are subject to wear and tear. Regular lubrication, tightening of loose components, and replacing worn parts are necessary to keep the unit running smoothly. This not only extends the lifespan of the unit but also prevents unexpected breakdowns.

Preventative Maintenance Programs:

A well-structured preventative maintenance program is vital to the longevity and efficiency of MAUs. This program should include scheduled inspections, routine cleaning, and predictive repairs. By anticipating potential issues and addressing them proactively, businesses can significantly reduce the risk of unexpected downtimes and costly emergency repairs.

Energy Efficiency Checks:

Regular maintenance also involves checking the energy efficiency of the unit. This includes inspecting and cleaning heat exchangers, ensuring proper fan operation, and verifying that control systems function optimally. The efficient operation of MAUs not only saves on energy costs but also contributes to the facility’s sustainability goals.

Record Keeping and Documentation:

Maintaining accurate records of all maintenance activities, repairs, and replacements is crucial. This documentation helps track the unit’s performance over time, plan future maintenance activities, and ensure compliance with regulatory standards.

In summary, proper maintenance of Industrial Make-Up Air Units is a multifaceted task that requires regular and detailed attention. By adhering to a comprehensive maintenance schedule, businesses can ensure that their MAUs operate at peak efficiency, providing clean, fresh air to their facilities while minimizing energy consumption and avoiding costly breakdowns.

Working with Kelowna HVAC Experts: Husky Heating and Cooling

For businesses in Kelowna requiring expertise in MAUs, Husky Heating and Cooling offers a wealth of experience. With 17 years in the industry, our team provides professional HVAC and refrigeration services, encompassing everything from routine maintenance to complex installations. Our commitment to honesty, professionalism, and exceptional service has earned us a reputation for excellence in the Okanagan area. As a full-service HVAC contractor, Husky Heating and Cooling can address any scale of HVAC challenges with our proven track record of exceeding customer expectations.